Design and Specifications of Mercedes Sprinter Ambulance by ICU Automotive

1. Introduction to Mercedes Sprinter Ambulance

Mercedes Sprinter Ambulance; An ambulance is a vehicle used to transport sick or injured individuals to healthcare facilities, often in an emergency. Such vehicles satisfy specific regulations aimed at decreasing the time necessary to reach an emergency department. These regulations are centered on security, traffic, and emergency requirements. Many vehicle manufacturers have created a variety of such automobiles. This fundamental demand inspired us to dedicate ourselves to the design and technological requirements of modern ICU transportation. Numerous emergency service providers from all around the world utilize ambulances. This is due to the fundamental capabilities they provide, including a large storage capacity, improved operational flexibility, simple organization, rapid mobilization, comfort, and operation. This automobile, with its powerful technology and brand, large load space, simple operating system, and capability to transport various seriously injured patients, is one of the most highly preferred ambulances used by health institutions. Because of its integral safety, profitability, length, width, height, and cargo capacity, it is every ambulance brand preferred by the dealership. Brazil, Vietnam, Saudi Arabia, Qatar, Kuwait, and the United Arab Emirates are some of the nations where ambulances are in widespread use. The purpose, usage, and type of options are carefully tailored to the requirements of the regions where these ambulances are being sold. However, the qualities of these vehicles, which have various standards for each healthcare institution, are the same worldwide.

1.1. Overview of ICU Automotive

1.1. Overview

An Iskumru Corporation & Brand ICO Moving Tek. Ltd. ICU Automotive’s factory is located in Duzce, Turkey. The company was founded in 2003. ICU Automotive started its business with the completed project ambulance vehicle, later developed and established its sub-companies, Isotek, Suetek, and Diabaz. With a current annual production capacity of 1,500 vehicles in total, ICU Automotive manufactures customized emergency vehicles designed specifically for the purpose of the service.

Mercedes-Benz has produced the Sprinter light commercial vehicle since 1995. The third-generation Sprinter was introduced in 2018 and is exceptionally efficient, flexible, and safe. It meets a wide range of requirements and gives new meaning to the concepts of usability, adaptability, and efficiency. Exceptional versatility starts with vehicle length variants and vehicle bodies (panel van, people carrier, chassis cab, and bus). There are several safety features on the Sprinter. The standard features also include services, a full content passenger compartment, a 4-cylinder diesel engine, a radio, a metallic body color, a reverse warning system, and a reversing camera. ICU Automotive aims to continue providing innovative solutions to increase the success of healthcare professionals, mainly for pre-hospital emergency healthcare services. Attracting attention with the manufacturing speed and process, as well as the concept of the vehicle produced, ICU Automotive is working with a high cooperation concept as a company and administration.

While a successful project is the result of a successful team, care is taken to ensure that all the employees in the production area work in complete safety and satisfaction. The vehicles and concepts produced are monitored from the design to customer feedback. Thus, the needs and problems encountered in the project process are detected at an early stage. Being ready with intelligent solutions under challenging conditions is one of ICU Automotive’s core values. ICU Automotive has proved its success in the field of ambulance by introducing the first Universal Volume ICU Ambulance to the world. ICU = ICU (Intensive Care Unit) = Intensive Care. The idea that this should be accessible to everyone at all ages, especially for patient evacuation, is that it can be used with all equipment in the volume of the vehicle and that no volume problem will be experienced in the ambulance. Thus, we designed the first all-in-one concept full volume ambulance, “SMART,” on a Sprinter-based vehicle. Currently, we have different Sprinter ambulance models offering this system with three different dimensions in three different sizes and two different brand options. Development and manufacturing are made by ICU Automotive. These remarkable designs are the result of 14 years of continuous R&D and feedback received from end users. Our modular structure, designed according to healthcare personnel needs in pre-hospital patient support, will be evaluated by you or your authorized technician as “MAX” during the recording according to the opinion of the users. Our launch has been done after successful general controls and tests in terms of design, construction, paint, measurement, equipment tolerances, electrical and electronic infrastructure, and advanced driving systems until the arrival of the Head Office Resident Team to our facilities.

2. Key Features and Design Elements

The Mercedes Sprinter ambulance features ABS, ASR, hill start assist, ESP, tyre-pressure monitoring system, attachment for the stretcher, a 2,500-watt inverter, and a separate power supply unit to convert solar energy for an additional 230-volt onboard supply. The completely new, three-part LED signal tone system also contributes to increased safety and efficiency. Impressive visual improvements of the new design are also visible on the exterior of the new base vehicle. It now features the new front with innovative LED outline lighting and LED daytime running lights. New rear lamps and the large operating position also stand out; the new ABS-reinforced rear doors improve ergonomics even further than before as they now open out to an angle of 270 degrees. The new version is also equipped with a reversing camera and a reversing radar with an acoustic signal. The 170-hp base vehicle is superior to its predecessor with a maximum torque of 380 Nm. The interior has also been significantly improved compared to the manufacturer’s high-quality interior fittings. Two practical wide-format drawers designed specifically for use make use of the interior space even more efficient.

The security package of the Mercedes Sprinter ambulance includes Dynamic Assist, ESP, Crosswind Assist, ABS, ASR, brake lights with adaptive flashing, wet brake assist, hill start assist, speed regulator, rain/light sensor, windshield wiper with rain sensor and adjustable wiper interval, automated headlamp activation, daytime running lights, warning signal when the driver has reduced attention, anti-theft protection package with anti-tampering protection for all locks, three-point safety belts including inflexible fixtures and automatic retracting shoulder belt for all seats, front airbags for the driver and front passenger, an anti-theft alarm system, three-point safety belt with automatic height adjuster, pre-tensioner and force limiter for outer seats in the first row of seats, disc brakes on the front and back axle, brake assist and electronic brake force distribution, tyre pressure monitoring system, load recognition, emergency brake lights, fuel pump cut-off in the event of an accident along with flashing hazard warning light, first-aid kit, warning triangle, and parking brake with release lever for handbrake.

2.1. Vehicle Dimensions and Layout

The ambulance is based on the Mercedes Sprinter chassis and features a full vehicle conversion, maintaining an aggressive and functional design language offered in the range of the main product of ICULIFE ambulances. Spacious, flexible, and built to meet the demands of different socio-economic settings, our design is evidence of our philosophy to integrate form and function.

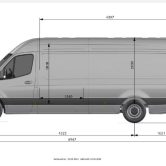

2.1. Vehicle Dimensions and Layout The overall length of this vehicle is based on the chassis type selected, ranging from 5490 to 5920 millimeters. The maximum width of this vehicle is 2061 mm, and it is 2825 mm high. Its rearview mirrors are 3052 mm wide, and from the floor to the top of the mirrors, it is 3052 mm high. The internal width of this vehicle, with skirts, is 1913 mm. The maximum internal height is 1785 mm, making it possible for medical personnel to work inside, while for customer-specific choice and patient safety, its service height is 1795 mm. The internal width minus the skirt is 1546 mm with a floor width of 967 mm. This internal width is spacious enough for a patient to be transported on a stretcher but low enough that the ambulance is still externally identifiable and designed in proportion to the van. Inside, the layout is multizone with an equipment compartment under the seats, an area for medical staff to move around in emergencies, and an equal bishop folded layout. This indicates that the two patients may be cared for on the table at the same time with the material in the middle of the vehicle. On examination, the design focuses on the ambulance rear, where the patients will spend the most time before being unloaded from the vehicle.

The maximum internal width available for an equipment compartment is 535 mm, optimizing the design to fulfill all the medical team’s requirements. The s-line layout is customizable according to your specific requirements: from a simple medical inspection to a home-to-hospital transport up to a complex ICU. The available internal space on both sides of the s-line layout, from the doors up to the area, is 1250 mm long and 2015 mm high. The ambulance’s external dimensions optimize the design to address the needs of low weight and continuous driving: perimeter rims protect the cover for the flash and flood lights. The icons show under what types of fleet such advice must be fit. The s-line layout provides a photographic layout of the ambulance floor plan. A number of factors need to be considered in determining the overall dimensions of the ambulance vehicle.

2.2. Medical Equipment Integration

One pivotal aspect of ambulance design is the seamless integration of medical equipment. In emergencies, patients often require critical lifesaving treatments. Trauma care, for instance, relies on a functional and readily accessible mobile pharmacy, a mobile intensive care unit, and essential technical equipment. An ambulance thus must be capable of transporting and operating a wide variety of essential medical equipment. In order to implement a quick and efficient workflow for the medical personnel, the ambulance must be easy to understand and intuitive to use. The ambulance is set up like a small ICU: the layout and placement of the tools and functions are designed according to the principle of the golden hour.

The three isolation systems as well as the treatment room layout are designed to meet the required structural safety energy absorption. Iconography highlighting the PPE discarding protocol is applied to the interior to assist the staff with removing contaminated PPE after use. All medical equipment in the treatment room and isolation areas is secured with trolley brackets against vibration and mechanical trauma. Universal rails have been attached to the side wall to accommodate the two ventilation devices required by the client. Multiple options for the type and quantity of medical equipment can be installed inside the ICU ambulance according to the client’s preferences. Such options for compatibility of the design with a wide range of equipment allow the client full adaptation of the idea of using the vehicle as an ICU to their operational needs. The ICU ambulance partitions with plexiglass windows ensure the safety of the medical personnel and patient.

3. Safety Features and Regulations

As paramedics responding to medical emergencies must have absolute confidence in the vehicle that conveys them, the Mercedes Sprinter Ambulance is designed and manufactured as a safe deployable hospital room. In addition to standard safety measures incorporated by the manufacturer and custom safety features, the vehicle is designed to perform under a variety of conditions beyond its intended use on the road. To ensure complete safety, crash testing procedures, as well as extensive analysis, were performed using fully laden ambulances to replicate real-world response scenarios. Safety features that are fitted to this ambulance include options such as collision prevention assistance, side-wind assistance, lane-keeping assistance, and acoustic reversing aid. Vehicle build requires a robust structure to accept the weight of added medical equipment and personnel and contribute to reducing the warp of the vehicle in a collision. Surface-mounted hardware and medical equipment on the walls of the vehicle must be able to withstand multiple G-forces without dislodging from their fastenings.

Especially when transport is conducted in emergency conditions, the safety functions of an ambulance respond reliably after the fact. With respect to vehicle design and construction, the vehicle must conform to the National Standard which governs mechanical structure and safety, exhaust emissions, and braking performance. The ambulance and associated equipment must comply with the National Road Traffic Regulations and additional standards and regulations as specified in the specification. In the event of an emergency stop, the braking system must bring the fully laden vehicle to a stop within acceptable braking distance and bring the vehicle to a stop on gradients down to eighteen percent. This is an integral part of the vehicle safety integrity. Specifications for the ambulance and its fitted equipment include full medical retrieval function, abilities to accept cardiopulmonary resuscitation (CPR) compressions during transport without interruption, mass casualty incident (MCI) response function, safety features for patient and crew, patient and crew ergonomic and comfort features, and systems monitoring considerations for a new and used vehicle. The following is a list of specific vehicle safety features.

Regulatory Requirements It is essential that an ambulance is compliant with the National Vehicle Standards, and it should be manufactured and certified under a quality management regime. An ambulance can only be licensed to operate if it is built and assembled in compliance with mandatory facts which may be deemed essential standards. In Australia, all ambulances are subject to an initial load compliance, including compliance audits by the requested authority after manufacture. The manufacturer undertakes this routine and annual process as part of its compliance with the relevant design rules. It is imperative that the design, manufacture, equipment selection, and testing meet the goals of both the manufacturer and the ambulance operators in providing optimal protection for both medical staff and patients during operation. In testing the vehicle, the ambulance application was deemed to be robust, and the safety testing results below were achieved having been tested with three crew members dispersed within the vehicle weighing up to 91 kg per crew member. Inside were lightweight patient trolleys and phantoms representing up to two typical patients for a combined weight of 172 kg representing the design limits of the flooring of between 120-300 kg. The vehicle currently has three module variations tested so far.

3.1. Crash Test Performance Mercedes Sprinter Ambulance

Currently, the ambulance has undergone two crash tests according to European standards. In addition, mobility tests were performed according to European standards and German standards. The tests are conducted to ensure that the design of the ambulance meets all the requirements for crash behavior with regard to vehicle-user interaction and to avoid loosening the supplies. The vehicle and ambulance user are well protected by the bed in the back of the vehicle, which converts into a stretcher. For the user, requirements have been defined in general for the stretcher system. The ambulance can carry two bed occupants in addition to the medical crew, or one bed with an accompanying occupant stretcher, which is transported longitudinally in the rear cabin. One occupant can be seated in the stretcher area; otherwise, full access is permitted when the stretcher is not there. The lining protection is in line with that proposed by the European Standard. An R20 certification test of the ambulance is unlikely with a high probability, as the ambulance is a single-stage vehicle and has a maximum mass of 4350 kg.

In the crash test of the ambulance, the requirements of regulation were met. Based on the performance of the crash test, no changes to the vehicle that cause a substantial increase in the safety of the passengers are necessary. However, based on the result of the crash test, a minor improvement regarding details would need to be done. The first crash test of the ambulance was an offset impact test according to the relevant regulation. This crash test also acts as a representative test for the ADA. A second crash test was a lateral impact crash test according to the requirements of regulation. No data from the crash test are given as the crash test report is still confidential. When looking at the detail of the crash test result, only minor changes were necessary on the special equipment in the available area around the bed to ensure that it can protect the patient against the requirements.

3.2. Compliance with Industry Standards Mercedes Sprinter Ambulance

This indicates that this vehicle is manufactured to conform to the national and international standards and guidelines of various regulatory bodies in order to ensure compliance. Various certifications are performed for these criteria to ensure that this product is performing correctly according to the specifications. The National Technical Regulation Certificate, Special Purpose Vehicle, Certificate of Design, EMC certificate, and ESEV certificate are some of the main certifications that are obtained prior to commencing the assembly process. For each one of the certifications, there are separate institutions or organizations that carry out the certification process. Technical and non-technical provisions for vehicle manufacturing are provided while also delivering mutual recognition of industrial regulations for automotive standards. Authorization and technical documentation that verifies the vehicle performs as specified and keeps its original description after approval, along with its identification stickers that indicate the vehicle has obtained Whole Vehicle Type Approval in any Member Country. While manufacturing organizations that wish to display their vehicles at exhibitions and presentations are required to submit a design and concept description, as well as other information required, such as diesel engine emission testing. The Sprinter Ambulance manufactured has been issued Product Certification by a world-class conformity standards body and one of the first of its kind established in Africa. The manufacturer also holds certification, minimally indicating conformity with these requirements. The basics of harmonization and its technical rules are based on new approach directives in which the regulatory authority is mandated according to proclamation for drugs and medicine framework. The ambulance design is broadly consistent with one or all of the following standards: The Deluxe Right-Hand Drive Ambulance is designed according to relevant standards.

4. Customization Options and Clientele Mercedes Sprinter Ambulance

Although the Mercedes Sprinter Ambulance was designed to incorporate the needs and services of various healthcare providers, the customization options are very extensive to meet the specific and particular needs of specialties or service providers. The design is done with a balanced focus between the configuration for highly interior clinical areas in one scenario and the specific driver’s seat operation in quite different driving postures with another external look, only by customizing the exterior or interior, in any case needed by the following services: Exterior Side Access Door with Storage Seats, Siren Lights, Exterior Side Access Door with Storage Seats, Siren Lights. According to the ICU customers market, service profile, and activities, the configurable interior could be different for each client. The case studies in the following pages demonstrate that with a single design at the origin, the ICU Sprinter Ambulances can change dynamically regardless of the destination customer and be customizable at any point via the change of configuration (from the exterior or by the internal resources). In other words, the ambulance design is scalable in both its off-roading and interior versatility. The case of Lecco hospital offers a wide operational profile. It focused on the needs of first assistance and attracted clients of various ages and illness conditions. The service is intended for stable, non-trauma-critical patients, traditionally called “non-code” services. It therefore meets the majority of emergency patients requiring hospital treatment. The case of Pescara speaks with even greater detail. In the Pescara Hospital, these are the substantial adjustments made to the ICU Sprinter. In this case, the vehicle is configured mainly for General Practitioner calls to doctor houses. In Pescara, with the ongoing service profile, sometimes even patients need to be taken to the Casualty Room, unlike Lecco. In this case, a patient who requires medical care at home by the GP is stable (not critical). This vehicle looks a lot like a “doctor house call SAV” with a defibrillator and electrocardiograph. In this way, visits to the doctor’s office are avoided by closely monitoring the patient at home, thus avoiding unnecessary crowding and overload of the Casualty Room. The combination of the two vehicles is in the Test Set point, hundreds of kilometers from the plant. The Lecco and Pescara initiatives are a clear example of the customization of the interior furnishings. The transformation suitable for more than 50 activities depends on their current needs. The possibility of conversion from the “ALFA” configuration to the “BETA/BRVO/GAMMA” one and vice versa by multiple operators was carried out to best meet the needs of the ICUs, ensuring the comfort breaking point, clean feed. Different configurations of the side door are also examined, including the multi-positions and no-door models of the PAs. These two medical/health case studies underline the strengths of customizing an ambulance, specializing in thousands of performances to give a greater quality of patient care. The presentation of the vehicle was made, proudly, during two “Days” by the parties involved in the various projects.

4.1. Tailored Interior Configurations Mercedes Sprinter Ambulance

Alongside the manufacturing of standard layouts, the Mercedes Sprinter has also been designed for an alternative interior ambulance fit-out with a total of four different floor plans offered as a special configuration. All the layout configurations are designed to optimize the use of the medical vehicle space based on the medical professionals’ needs. The treatment area in the rear of the vehicle is equipped with the latest medical technological devices, such as a defibrillator, ventilator, and infusion pumps. A different ambiguity room allows the vehicle to be configured for use in different medical emergencies: the treatment and care of dehydrated children, the management of diseases or complicated patients downstairs, and the personal evacuation of patients who cannot be removed from their home. Modularity and versatility are supported by easy access and use of equipment. The large working area available in the ambulance can be equipped with one or up to two medical device tables according to the desired layout, where to install all the necessary equipment to provide first aid to patients. The ambulance is also equipped with modern personal safety devices for the patient during transport. The bodybuilder pays special attention to the interior of the ambulance, where the medical operators are trained and operated. In the same way, special attention is paid to the medical devices room, which is cleanable and sanitizable. All electrical connections are available to connect medical device machines. The intensive care Mercedes ambulance is equipped with more advanced medical technological features. During the design phase, our team guarantees the access of at least two clinicians to the patient. The ambulance is also equipped with an electric chair lift to go upstairs, a stair push-on system, and an electric winch to move the patient.

4.2. Client Case Studies

Two case studies are presented below to show examples for two strategic populations that are utilizing the Mercedes Sprinter Ambulance with the customization assistance of ICU Automotive. Though the client populations interfacing with the ambulance are different, the technological applications and operational experiences of the ambulance in the two localities are not dissimilar.

1. Wadsworth Paramedics Wadsworth paramedics serve the emergency medical needs of a rural community in the northwest of the USA. Typically, Wadsworth has a call volume of 1,200 calls per year, with half of those being urgent medical cases. Their unique operational requirements led to an introduction to ICU Automotive. A primary interest in expanding the emergency medical service to a high-volume location (population of 5,200 that is currently served on a paramedic interceptor basis), where over 55,000 visitors (with significant medical needs due to high temperatures and people not acclimated to the elevation) may congregate, led to the identification of the ICU Ambulance as the solution.

2. International Hospital (I-Hospital) From the very beginning of this initiative, ICU Automotive had a close working relationship with I-Hospital. Based in Qena, Egypt, I-Hospital has a small 20-bed hospital in the city adjacent to the Nile, with around 40 health centers in the surrounding areas. I-Hospital also has three clinics currently under construction in tourist areas. Qena Governorate is a governorate of Upper Egypt, surrounded on the north by Asyut Governorate, on the east by the Red Sea, on the south by Luxor Governorate, and on the west by Sohag Governorate. It covers nearly 15 percent of Egypt; however, the governorate has one of the lowest total population counts of approximately 3,000,000. Similar to other fruits of this field of the larger project, I-Hospital will be conducting research on the “World’s First Mobile Hospital.” According to some experts working on this initiative, I-Hospital is the only facility that will attempt to reach universal access in this manner. Thus, data collection throughout all stages of the mobile hospital will provide evidence on the possibility of maximum flexible readiness for the provision of a continuum of care anywhere, anytime.

5. Future Developments and Innovation Mercedes Sprinter Ambulance

5.1 Research and Development

Nowadays, many research and development activities are ongoing in various automotive fields to improve performance or expand usability, driven by the extra or different requirements in the medical and patient care sectors. Moreover, the healthcare sector is in continuous research and change since there has always been a need for increasingly efficient hands-on care, together with the development of more proactive and wellness-based approaches. To aid in promoting and meeting such medical business innovations, medical emergency vehicles may require onboard advanced technologies. Predictability and the assumption of it are the two main aspects of future commercial ambulances, and these are taken as the principal constraints both explicitly when modeling and implicitly when pricing values and futures. It is important to note that, because of data disclosure agreements, or even in light of any legislative benefits in the future, we cannot yet be sure of these mutually exclusive assumptions.

5.2 Material for the Future

A growing trend indicates that the healthcare industry, as well as government and environmental intermediaries, is requiring innovation toward sustainability. One product of this is the development and manufacture of medical devices with advanced, increasingly eco-friendly materials to improve performance, safety, ease of maintenance, and sustainability, thus promoting sustainability in the healthcare industry. Inspiration for specifically bio-based materials was drawn from systematizing eco-friendly and bio-based resources for the manufacture of heavy and transit vehicles, as diesel multiple units showed interest in approaches aligning with future developments of ambulance technologies to meet new European standards and requirements. We found an approach wherein the selection of appropriate materials based on fiber and orientation can improve or degrade the physical properties of materials, while in the automotive industry, bio-based resin systems are at the beginning stage of their development and application. Developing materials with a specified reinforcing system can change the total weight of such an ambulance vehicle, thereby exponentially increasing energy efficiency and environmental performance by controlling the emissions of greenhouse gases.

5.3 Future Needs of Outfit and Internal Spaces

Future developments are expected in the healthcare markets, which will impact the design and outfit of ambulances. ICU Automotive wants to be a front-runner in this development, to be involved sooner in testing and experiences of these developments. A new possible organization of workshops: the rapid-transformation workshops are popular in times of great upheaval, such as when a rapid response is required to solve problems. A rapid-response team is pulled together for a determined time frame for a “deep dive” into a specific topic with a defined set of deliverables. Organizations need a safe, focused space for innovating and experimenting. This is a comfort: your business is robust, our organization is dynamic, our society is strong. The ambulance vehicles and the internal outfit could be designed to improve response time to infection or contagion events by using an effective cleaning system with the environment. Our sketches or considerations were drawn from an ICU ambulance manufacturer’s point of view, considering our wide and long-established experience in the market of emergency healthcare vehicles. This way, this paper aims to promote interest among stakeholders, companies, and users in order to establish a deep and efficient relationship in research and development to cope with an emergency or a monitorable item, understanding critical topics to satisfy a quantity requirement.

5.1. Technological Advancements Mercedes Sprinter Ambulance

The Mercedes Sprinter Ambulance is designed and manufactured with several unique features that make it a standout ambulance in the market. Integration of advanced telematics, the ability for remote monitoring, real-time monitoring of patient vitals and geolocations on the map, and an extensive digital healthcare suite are a few of the key features that have been incorporated into the ambulance design to provide the highest operational efficiencies and effectively monitor the patient’s condition during the on-road journey at any given point in time. This also ensures access by touch to doctors in real time in case of complications or any other requirements during transit. The digital healthcare suite also ensures digitization and integration of ambulance operations at the hospitals to facilitate seamless communication between the hospital ICT infrastructure and the e-Van operations in fields claimed by hospitals as direct benefits.

We are living in an era of the internet and digitization, and armed with a robust research and development team of 150 engineers, five technical collaborations with leading technology institutes in the world, and establishments to develop future technologies and exoskeletons, we have advancements in technology that we are currently working on. The new age technology will enable instant communication of patient location or troubling circumstances to the hospital teams. A gadget-based workload distribution to the hospitals rather than drivers knocking on their doors for human assistance. Automate the ambulance to take real-time medical action rather than waiting for human physical medical action. Precision in the drive decision is aided by instrumental judgment. Further, all the technologies have a global fitment, and the ICU is open to discussing technology transfer with the customers of our future technologies.